Culvert construction in Ghana is a critical part of road works, drainage systems, and infrastructure development in the country. When properly designed and installed, culverts safely convey water beneath roads, driveways, railways, and embankments, preventing flooding, erosion, and structural failure.

Contact us for all your culvert needs: 0243174009

Poor culvert construction, however, can lead to collapsed roads, blocked drainage, and costly repairs. This guide explains how culvert construction works, the materials used, and best practices suitable for Ghanaian conditions.

What Is Culvert Construction?

Culvert construction is the process of designing, installing, and protecting a culvert structure that allows water to pass under a roadway or structure.

In Ghana, culvert construction is commonly used in road projects, housing estates, industrial zones, agricultural areas, and flood control schemes. Most culverts are constructed using precast concrete pipes or box culverts because of their strength and durability.

Importance of Proper Culvert Construction in Ghana

Due to Ghana’s heavy rainfall patterns and varying soil conditions, culvert construction must be done correctly to avoid washouts and flooding. Proper culvert construction ensures smooth water flow, protects road foundations, reduces erosion, and extends the lifespan of infrastructure.

Government agencies, contractors, and private developers rely on standard culvert construction methods to meet safety and engineering requirements.

Common Materials Used in Culvert Construction

The choice of material greatly affects the performance and longevity of a culvert.

Concrete culverts are the most widely used in Ghana. They offer high load-bearing capacity, resistance to corrosion, and long service life. Precast concrete culverts are preferred because they are manufactured under controlled conditions and meet Ghana Standards Authority requirements.

Steel culverts are sometimes used for temporary works but are less common due to corrosion risks in wet environments.

Read also: Best Culvert Price in Ghana: Types, Sizes & Buying Guide!

Plastic or HDPE culverts may be used for small drainage applications but are generally unsuitable for heavy traffic or major road projects.

For long-term infrastructure, concrete culverts remain the best option for culvert construction in Ghana.

Step-by-Step Culvert Construction Process

Culvert construction follows a structured process to ensure safety and durability.

The first step is site assessment and design. Engineers assess the catchment area, expected water flow, soil conditions, and traffic load. This helps determine the correct culvert size, type, and alignment.

Next is excavation. The trench is excavated to the required depth and width, ensuring proper slope for water flow. Poor excavation can lead to settlement and failure.

Bedding preparation follows. A stable bedding layer, usually sand or crushed stone, is laid to support the culvert evenly. Proper bedding prevents cracking and movement.

Installation of the culvert comes next. Precast concrete pipes or box culverts are carefully placed and aligned. Joints are sealed to prevent leakage and soil infiltration.

Backfilling and compaction are critical stages. Backfill material is placed in layers and compacted to provide structural support. Poor compaction is a common cause of culvert failure.

Finally, inlet and outlet protection is added. This includes headwalls, wing walls, or stone pitching to prevent erosion and improve water entry and exit.

Types of Culverts Used in Construction Projects

Several culvert types are used depending on project requirements.

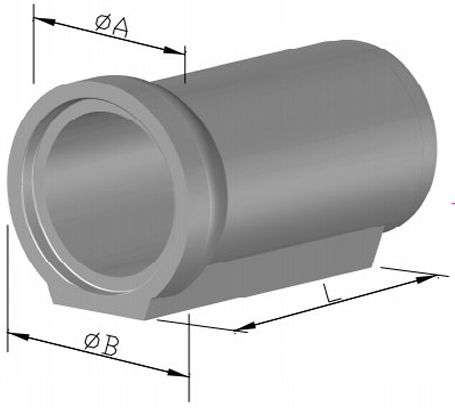

Pipe culverts are circular and commonly used for roads and drainage channels. They are simple, cost-effective, and easy to install.

Box culverts are rectangular and used where large volumes of water must pass through. They are common in highways and urban drainage systems.

Arch culverts allow water flow while maintaining a natural stream bed and are suitable for environmentally sensitive areas.

Selecting the right type is essential for effective culvert construction.

Common Mistakes in Culvert Construction

Many culvert failures in Ghana result from avoidable mistakes. Using undersized culverts leads to flooding during heavy rains. Poor bedding and backfilling cause settlement and cracking. Incorrect slope prevents proper water flow, leading to blockages. Using substandard materials reduces the lifespan of the culvert.

These issues can be avoided by following proper engineering practices and sourcing quality precast concrete culverts.

Culvert Construction Costs in Ghana

The cost of culvert construction depends on culvert size, type, excavation depth, installation complexity, and location. Concrete culvert prices also vary based on dimensions and reinforcement. While cheaper options may seem attractive, investing in quality culverts and professional installation reduces long-term maintenance and repair costs.

Maintenance After Culvert Construction

Even well-constructed culverts require periodic inspection and maintenance. Removing debris, clearing silt, and checking for erosion around inlets and outlets helps maintain performance. Regular maintenance extends the service life of culvert drainage systems.

Choosing the Right Culvert Supplier for Construction Projects

Successful culvert construction begins with choosing the right supplier. Experienced precast concrete manufacturers provide consistent quality, accurate dimensions, and expert advice. Working with a trusted supplier ensures compliance with standards and reliable delivery for your project timeline.

Final Thoughts on Culvert Construction

Culvert construction is a vital part of Ghana’s infrastructure development. Proper design, quality materials, skilled installation, and ongoing maintenance ensure safe water flow and durable roads.

Whether for road works, estates, or drainage systems, investing in correct culvert construction protects lives, property, and long-term project value.

For detailed culvert sizes, specifications, and pricing, always consult reliable precast concrete suppliers or manufacturers like us who understand Ghana’s construction environment.